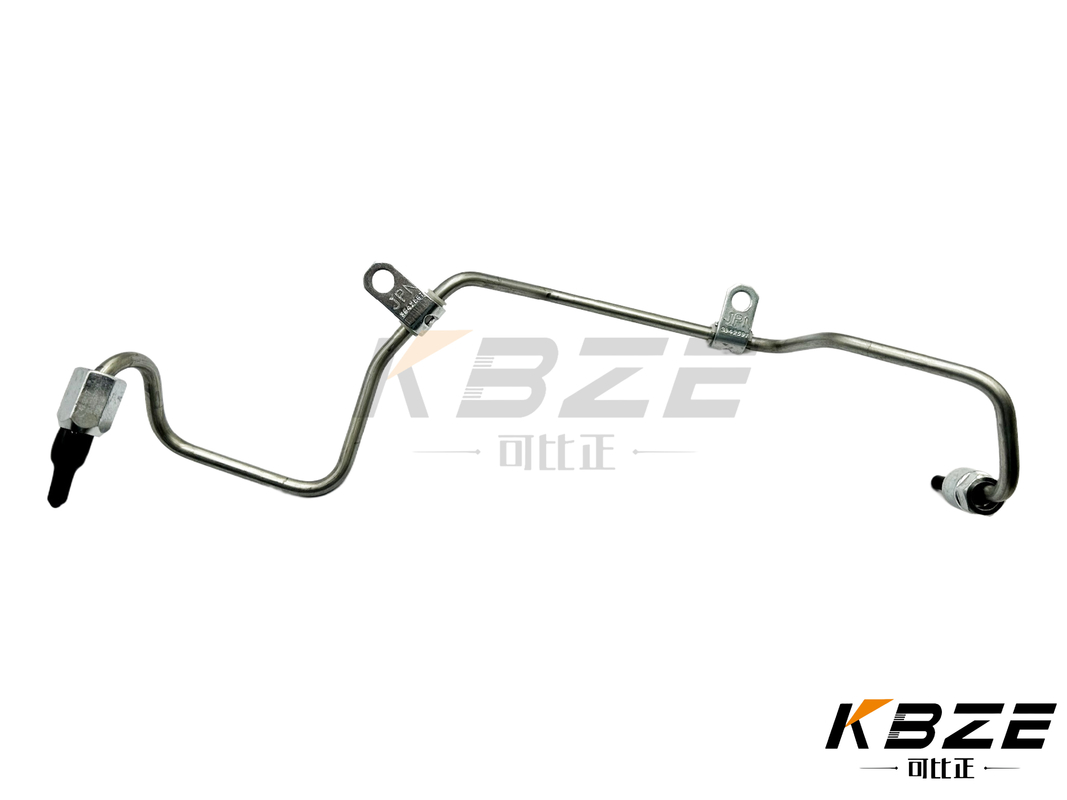

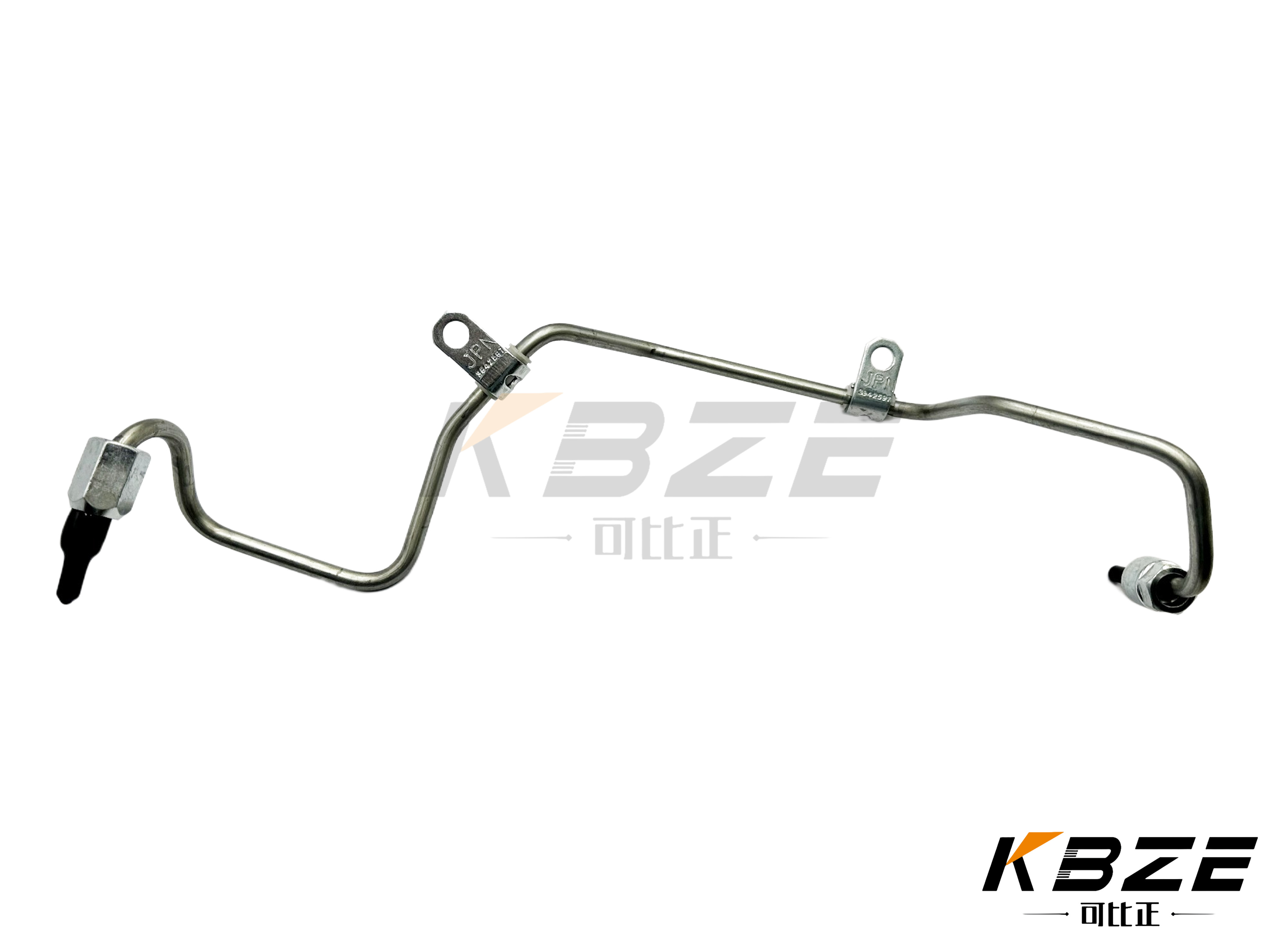

PRODUCT DESCRIPTION

| PRODUCT NAME: |

EXCAVATOR CUMMINS ENGINE QSB4.5 4933417/3942597 COMMON RAIL PIPE FIT ISDE DIESEL ENGINE

|

| PART NO: |

4933417/3942597 |

| BRAND NAME: |

KBZE COMMON RAIL PIPE |

| APPLICABLE MACHINE: |

CUMMINS QSB4.5 |

| SIZE: |

STANDARD |

| MOQ: |

WE ACCEPT TRIAL ORDER |

| PLACE OF ORIGIN: |

MADE IN CHINA |

| CONDITION: |

100% NEW GENUINE |

| CUSTOMIZED: |

OEM & ODM WELCOME |

| DELIVERY METHOD: |

AIR FREIGHT , SEA FREIGHT , DHL , FEDEX |

| PORT |

ANY PORT IN CHINA |

| SUITABLE MODEL: |

CUMMINS QSB4.5

|

Common Rail How To Work?

The "common rail" system is a crucial technology used in modern diesel engines to improve fuel efficiency, reduce emissions, and enhance engine performance. Here’s how it generally works:

1. **Fuel Supply:** Fuel is supplied from the fuel tank to a high-pressure pump.

2. **High-Pressure Pump:** The high-pressure pump (often a piston pump) pressurizes the fuel to extremely high pressures, typically ranging from 1,000 to 3,000 bar (14,500 to 43,500 psi).

3. **Common Rail:** From the high-pressure pump, the pressurized fuel is sent to a common rail, which is a reservoir that stores the pressurized fuel at constant high pressure.

4. **Injectors:** Each cylinder of the engine has an injector connected to the common rail. These injectors are electronically controlled and precisely time the injection of fuel into the combustion chamber.

5. **Injection Timing and Pressure Control:** The timing and pressure of fuel injection are controlled electronically by the engine control unit (ECU) based on various engine parameters such as speed, load, temperature, and emissions requirements.

6. **Injection Process:** During the combustion cycle, the injector opens and sprays a precisely metered amount of pressurized fuel into the combustion chamber. The high pressure ensures efficient atomization of the fuel, leading to better combustion and reduced emissions.

Advantages of Common Rail Technology:

- mproved Fuel Efficiency: Allows for more precise control over fuel injection, leading to better combustion efficiency.

- Lower Emissions: Enables cleaner combustion due to better atomization of fuel.

- Enhanced Performance: Provides more power and torque output while maintaining fuel economy.

- Quieter Operation:** Results in smoother and quieter engine operation compared to older diesel engine technologies.

Challenges:

- Cost: Common rail systems are more complex and expensive than traditional diesel fuel systems.

- Maintenance: Requires specialized knowledge and equipment for maintenance and repair.

- Durability:High-pressure components must withstand harsh operating conditions.

Overall, the common rail system represents a significant advancement in diesel engine technology, offering a balance between performance, efficiency, and emissions control that meets modern regulatory standards.

RELATED PRODUCTS:

PRODUCT SHOWS:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!